Flour Mills

General process: Removing impurities & sorting → Surface cleaning → Moisture adjustment, wheat conditioning & batching → Milling → Sifting → Purification → Flour collection & batching

Removing Impurities & Sorting

Drum Sieve

Drum dia. 630, 800, 1000, 1200; capacity: 20-80ton/hr

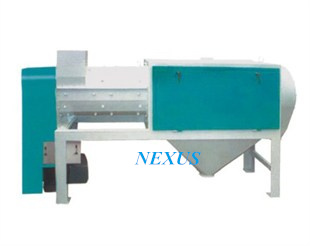

Reciprocating Sieve

Max. capacity: 100ton/hr

Rotary Separator

Max. capacity 200ton/hr

Circulating Air Sorter

Max. capacity 26ton/hr

Aspiration Channel

Capacity 20ton/hr

Gravitation Grading Dry Stoner

Max. capacity 32-34ton/hr

Indented Cylinder

Capacity: 8-10t/hr

Disc Cylindrical Separator

Capacity: 8-10t/hr

Spiral Gravity Separator

Capacity: combined separators can reach treatment capacity 50-1000ton per day

Vertical Spout Magnet

Max capacity: 50-70t

Wheat Color Sorter

Capacity 1.5-7.5t/hr

Surface Cleaning

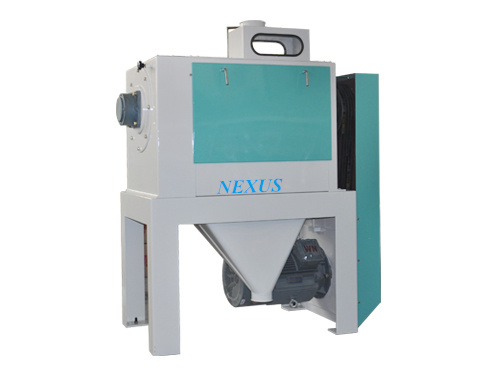

Horizontal Scourer

Capacity 5-20t/hr

Drum Scourer

Capacity: 20-50t/hr

Impact Scourer

Combined Wheat Scourer and Brush

Capacity 8-28t/hr

Vertical Barker

Capacity 1-20t/hr

Wheat Brush

Capacity 4-16t/hr

Wheat Washer, Stoner and Whizzer

Capacity 1-50t/hr

Moisture Adjustment, Wheat Conditioning & Batching

Dampener

Capacity 5-50t/hr

Moisture Control System

Wheat Conditioning & Batching

Milling

Pneumatic Grinder

Different roller diameter and length.

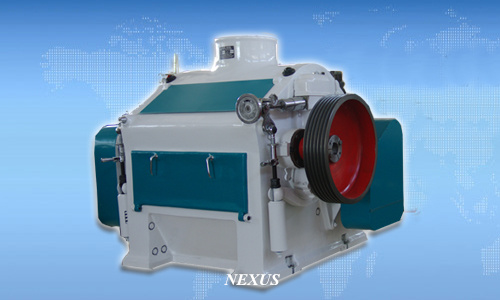

Hydraulic Grinder

Roller diameter 250mm; roller length 800/1000mm

Impact Detacher

Capacity 1-4t/hr

Drum Detacher

Capacity 1-2.5t/hr

Sifting

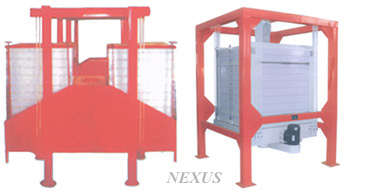

Square Plansifter

Different compartment & sieve frame arrangement available as per client’s requirements.

Bran Finisher

Capacity 1-2.5t/hr

Bran Brush

Different drum diameter and height.

Purification

Purifier

Different capacity.

Flour Collection & Batching

Mechanical & Pneumatic Conveying

Metal Removing & Weighing

Inspection Sieve & Pest Killing

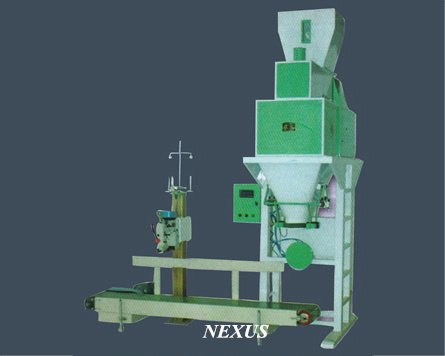

Microelement Scale, Conveying, Discharger, Batching Scale

Flour Mixer & Filling

Other Equipment & Components

Conveying & Stacking

Dedusting

Silo & Control System

Spare Parts & Accessories

Vibrator

Gearboxes of various kinds

Dust explosion proof motors

Screen grid

Purifier brushes

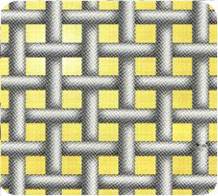

Screen mesh of different types

Mesh

Mesh

Destoner mesh

Rubber absorber

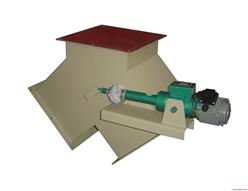

Rotary valve / Pneumatic lock

Stainless steel rotary valve

Discharge valve

Pneumatic valve

Motorized valve

Pneumatic tee

Motorized tee

Pneumatic clutch

Air cylinder

Pneumatic vibrator

Pneumatic hammer

Bottom bin discharger

Bearings for flour mill

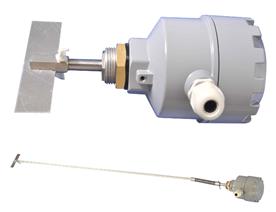

Level detector

Level detector

Roots blower

Centrifuge fan

Grain cooling machine

Insulated doors & windows

Ex proof fluorescent lamp

Ex proof junction boxes

Ex power distribution box

Ex delta starter

Ex roof ventilator

Roller Maintenance & Parts

Flour Mill Roller Hydraulic Grinding and Fluting Machine

- Roller diameter: ∮250-∮600mm

- Roller length: 500-3000mm

- Number of fluting: 100-1200flutes/circles

- Fluting inclination: ≦8°, or 1:7(14%)

- Accuracy of grinding: roughness not lower than Ra0.8

- Roller speed during grinding: 25rpm

- Grinding wheel speed: ≦1148rpm(or 20 meters/second)

- Table travel speed: about 1m/minute-10m/minute

- Center height: 350mm

- Total power: 12.75KW

- Dimension: 7500×1300×1500mm

- Weight: about 10T

Other models with diameter 400mm and length 1.5m or 2.5m are also available.

Roller Sand Blasting Machine

- Roller max. diameter: 300mm

- Roller length: 600-1250mm

- Max. sand blasting length: 1300mm

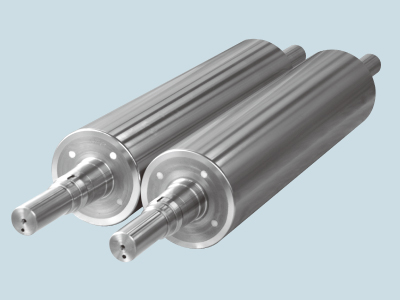

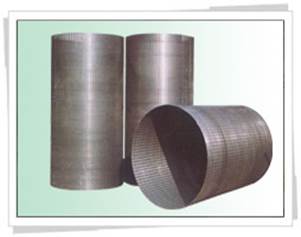

Flour Mill Roller Series

Characteristics of flour mill rollers:

- Vanadium alloy formula and automatic centrifugal casting are applied for roller fabrication.

- Imported spectrum from Germany is used for analysis to make sure correct alloy formula.

- Low hardness, high wear resistance, roller surface hardness 61-67HS, toothed roller hardness 68-74HS, more suitable for flour mill.

- Our flour mill rollers can ensure flour output and extend roller service life, reduce energy consumption, and effective improve flour milling plant comprehensive benefits.