Peanut, Peanut Butter, & Peanut Milk Processing Plant

Scope of project: EP contracting (design + procurement + installation/commissioning + training)

Final Products Gallery

Peanut Butter Processing Diagram

Harvesting → Drying → Washing → Husking → Destoning → Sieving → Baking → Cooling → Skinning → Sorting by Color → Batching → Rough Grinding → Fine Grinding → Filling → Capping → Labeling → Packing

Harvesting

Drying

Natural dry or dry by equipment.

Washing

Capacity 1000-1500kg/hr

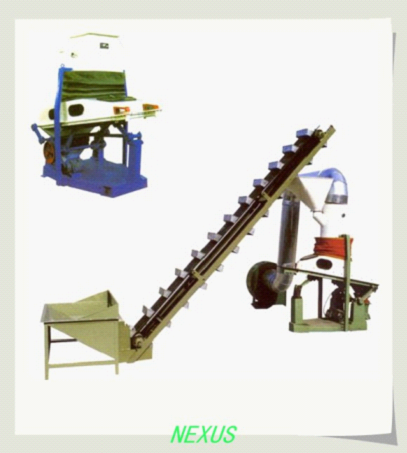

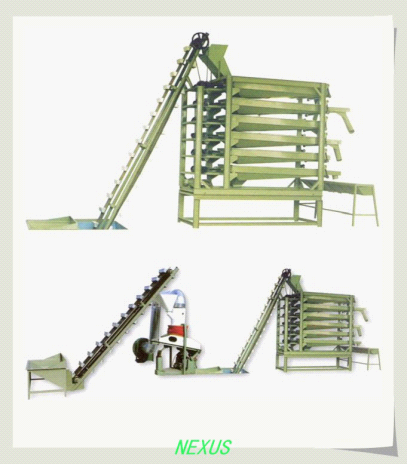

Husking

Capacity 500-2500kg/hr

Destoning

Because of different gravity between stone and peanut, the machine has good cleaning effects. Capacity 2-5t/hr

Sieving

Capacity 2-8t/hr, 4-5 grades sorting available.

Baking

Cooling

Skinning

Capacity 200kg/hr

Sorting by Color

Batching

Adding coco butter, sugar, monoglyceride, salt and other ingredients.

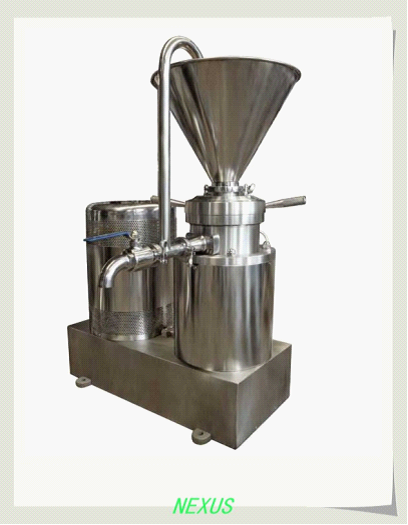

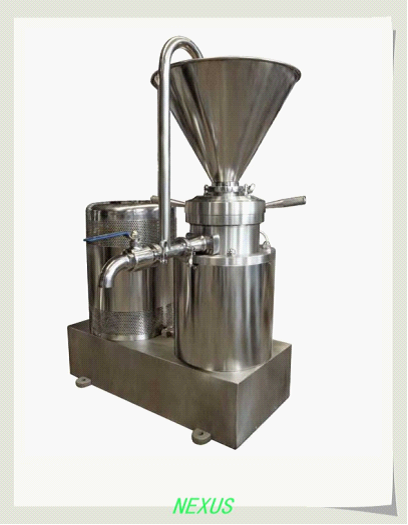

Rough Grinding

Capacity up to 40t/hr. Fineness up to 50μm

Fine Grinding

Capacity up to 8t/hr. Fineness: 2-40μm

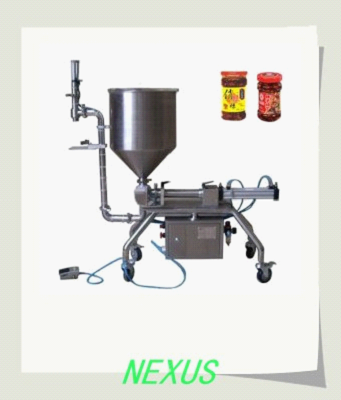

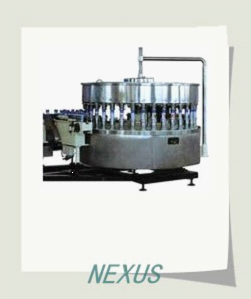

Filling, Capping, and Labeling

A comprehensive solution to your filling, capping, and labeling requirements is available.

Peanut Milk Processing Diagram

Peanut Kernel → Steeping → Grinding → Pulp Cooking → Batching → Homogenization → Filling → Capping → Pasteurization → Cooling → Inspection → Labeling → Finished Product → Warehousing

Peanut Kernel Steeping Tank

High quality peanut kernels shall be chosen as the raw material for peanut milk processing. Steeping duration 6 to 8 hours under temperature around 50°C to deactivate oxidase and remove bitter taste.

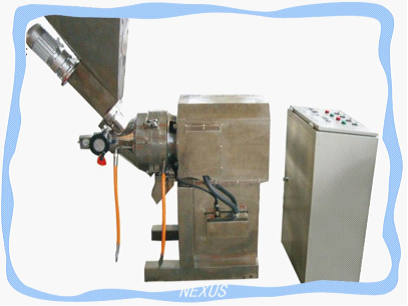

Rough Grinding

Different capacities are available.

Fine Grinding

Different capacities are available.

Milk and Residue Separation

Different capacities and mesh sizes are available.

Batching

Adding degreased milk powder, lysine, sugar, emulsifier, stabilizer etc into peanut milk.

Cooking

Then the milk is pumped into aging tank for heating up to certain temperature. The foams shall be removed and the heating duration time shall be under control so as to prevent precipitation.

UHT Sterilization

Degassing

To remove air generated during crushing, pulping, homogenizing, prevent or reduce loss of nutritious ingredients.

Homogenization

Used to crush & homogenize different particle sizes, increase delicate taste & flavor. The milk shall be homogenized twice under different pressure so that the protein and fat sizes are reduced to 1~2μm, and the emulsifier and stabilizer are fully integrated for good quality and long shelf life.

Filling, Capping, Sterilization, Labeling

Aseptic filling. The bottle and cap shall be sterilized before filling and capping. The peanut milk bottles shall be sterilized inside autoclave under certain temperature, pressure and duration for thorough sterilization.

Complete Peanut Processing Solutions

We provide full EP contracting for peanut butter and peanut milk production lines, from harvesting to packaging.

Request a Quote