Dates Processing Plant

Scope of project: EP contracting (design + procurement + installation/commissioning + training)

Final Products Gallery

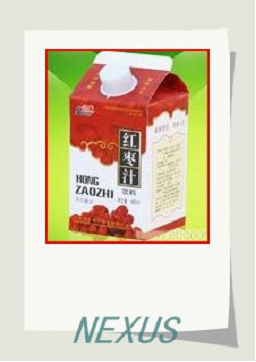

Dates Juice

Dates Juice

Dates Juice

Dates Juice

Dates Juice

Dates Juice

Dates Juice

Dates Instant Powder

Dates Biscuit

Dates Jam

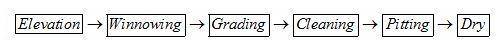

Processing Line

Elevator

We can supply different height, length, width as per customer's requirements.

Winnowing Machine

Used to remove grass, leaves, dust etc with air suction system.

Grading Machine

Choice of roll bar type grading, drum grading, cage grading, photoelectric grading.

1. Roll Bar Grading Machine

Different gaps are arranged between roll bars. When raw materials pass on roll bars, materials with different sizes will fall down to conveyor belts from different gaps.

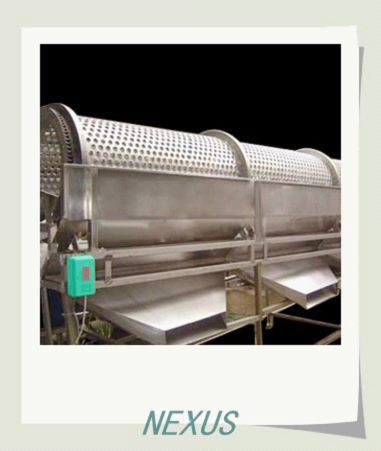

2. Drum Grading Machine

Holes with different diameters are arranged on the sieve. When materials pass through different holes, grading job is realized.

3. Cage Grading Machine

Suitable for long shape fruits.

4. Photoelectric Grading Machine

The system will conduct image fast processing according to fruit shape, size, color and external defect for fruit grading as per user requirements, making each grade of the fruits have the same appearance and quality. Different lanes and capacity are available.

Cleaning

Bubble Washing Machine:

Vortex pump is provided so as to create bubbles. The dates are vibrating on waves for good cleaning.

Brush Roll Washing Machine:

Used to clean hair and dirts inside the date folds.

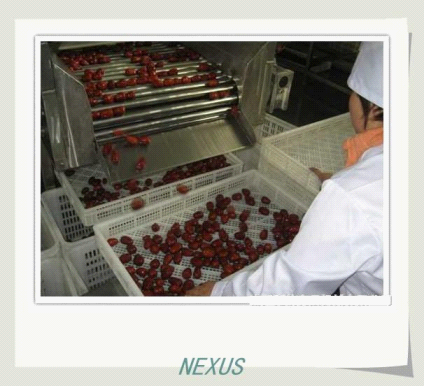

Pit Removing

Date Pit Removing Machine:

Feed the dates into the inlet, the dates enter through dies conveyor, then the machine will remove the pits automatically with a capacity about 150,000 dates/hr. It greatly increases efficiency and reduces labor force.

Dryers

Different choices like tunnel type, belt type, microwave type, vacuum type, microwave vacuum type etc are available.

Tunnel Drier

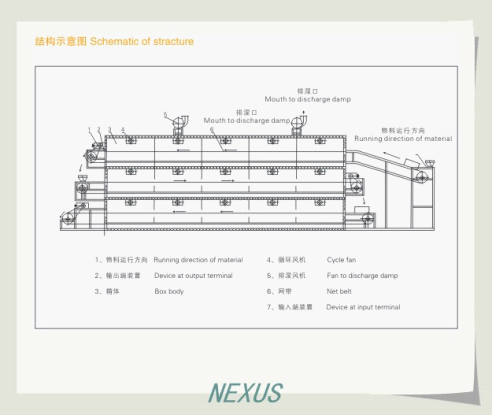

Multi-layer Belt Drier

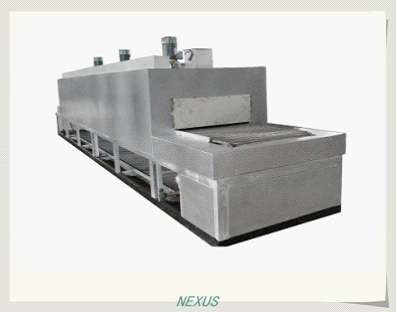

Microwave Drier

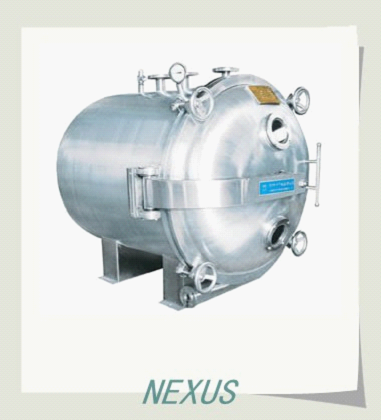

Vacuum Drier

Microwave Vacuum Drier

Process Continued for Juice Processing

Steeping / Pre-cooking ★ Pulping ★ Sterilization ★ Refining & Filtering ★ Homogenization ★ Degassing ★ Concentration ★ Filling ★ Capping ★ Pasteurization ★ Cooling ★ Labeling

Steeping Tank

Used for dates juice processing. The dates shall be crushed into certain sizes before feeding into the steeping tank. Mixer is provided for homogenization. Steeping effects rely on water filled, temperature, time and dates crushing.

Pre-cooking Machine

The purpose is to sterilize and soften the dates.

Three Channel Pulper

The first channel is for rough pulping, the second and third channels for fine pulping. The sieve diameters in the three channels can be selected according to the requirements of materials.

Sterilization

Plate type heat exchanger used to kill pathogenic bacteria and passivate pectin enzyme and prevent precipitation.

Refining & Filtering

Refining:

- 1. Pectin enzyme refining

- 2. Chitosan refining

- 3. Ultrafiltration

- 4. Resin absorption

Filtering:

To remove precipitated and suspended matters, sieving machine, and/or filtering machine will be used for the purpose.

Sieving machine

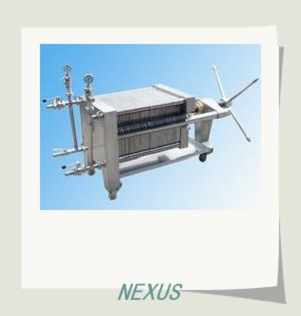

Paperboard filtering machine

Diatomaceous earth filtering machine

Homogenization

Used to crush & homogenize different particle sizes, increase delicate taste & flavor, and pectin exudation.

Degassing

To remove air generated during crushing, pulping, homogenizing, prevent or reduce loss of nutritious ingredients.

Concentration

Dehydration equipment to desired concentration degree.

Centrifugal thin film evaporator

Three-effect-evaporator

Filling, Capping, Pasteurizer, Labeling

For Instant Dates Powder Process

Choice of spray tower, belt type vacuum drier, horizontal fluidized bed drier.

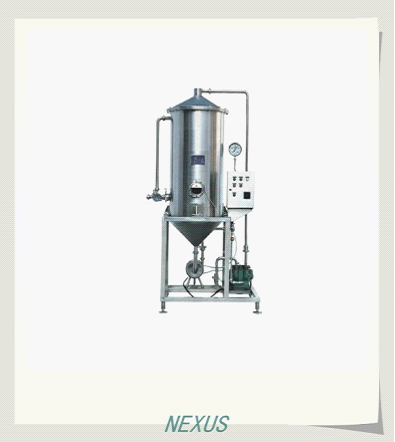

Spray Tower

After concentration, juice drops are distributed into hot air by mister. The powder falls because of gravity after evaporation and is collected.

Belt Type Vacuum Drier

Horizontal Fluidized Bed Drier

Complete Date Processing Plants

From simple drying and grading to complete juice and powder lines, we offer full EP contracting.

Request a Quote